Additive manufacturing, or 3D printing, has gone from being a specialized technology to a standard procedure in many industries. Small firms have benefited greatly from this transformation since it has given them the tools they need to compete with larger enterprises. They can now offer customized products, reduce production costs, and shorten time-to-market. 3D Printing for Custom Manufacturing is complicated, but this article simplifies it by going over its advantages, uses, problems, and potential solutions.

Key Takeaways:

- D printing enables the creation of unique, tailored products, allowing small businesses to offer bespoke items and mass customization efficiently.

- The technology reduces material waste and eliminates the need for expensive tooling, making it cost-effective for prototyping and small production runs.

- 3D printing accelerates the design process, allowing for quick iterations and faster time-to-market, with the possibility of in-house production.

- It provides design freedom, enabling the production of complex geometries and fostering innovation by allowing businesses to experiment with new product ideas.

Understanding 3D Printing

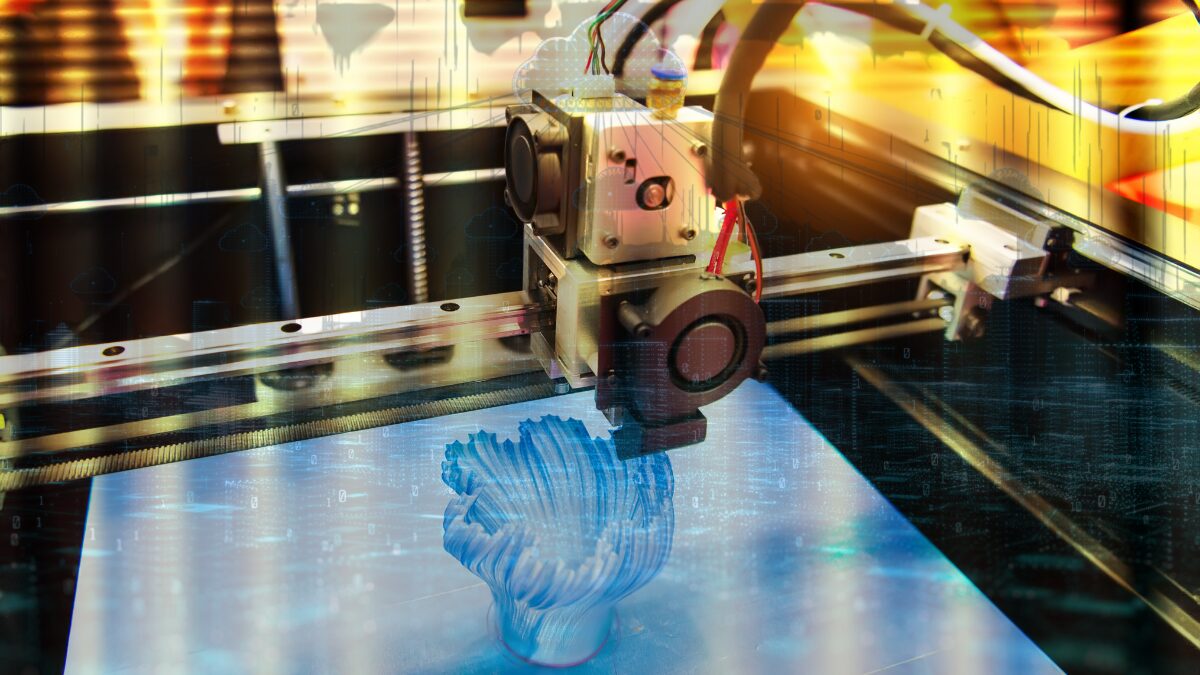

3D printing is a process of creating three-dimensional objects from a digital file, layer by layer. The primary types of 3D printing technologies include:

Fused Deposition Modeling (FDM): Uses thermoplastic filaments, which are melted and extruded to form layers.

Stereolithography (SLA): Utilizes a laser to cure liquid resin into hardened plastic in a layer-by-layer fashion.

Selective Laser Sintering (SLS): Employs a laser to sinter powdered material, binding it together to create a solid structure.

Digital Light Processing (DLP): Similar to SLA but uses a digital light projector screen to flash a single image of each layer all at once.

Each of these technologies offers distinct advantages and is suitable for different applications, making 3D printing a versatile tool for custom manufacturing.

Benefits of 3D Printing in Custom Manufacturing

Customization and Personalization:

Unique Products: 3D printing allows for the production of unique, one-off items tailored to individual customer specifications. This capability is invaluable in industries like healthcare (custom prosthetics), fashion (personalized jewelry), and consumer goods (custom phone cases).

Mass Customization: Small businesses can produce small batches of customized products without significant cost increases, enabling a blend of bespoke and mass production.

Cost Efficiency:

Reduced Waste: Traditional subtractive manufacturing methods often result in substantial material waste. In contrast, additive manufacturing only uses the material necessary to create the product, reducing waste and cost.

Lower Tooling Costs: 3D printing eliminates the need for expensive molds and tooling, which is especially beneficial for small production runs and prototypes.

Rapid Prototyping and Production:

Speed: 3D printing accelerates the design and prototyping phase, allowing for quick iterations and faster time-to-market.

In-House Production: Small businesses can manage production in-house, reducing reliance on external suppliers and shortening lead times.

Complexity and Innovation:

Design Freedom: 3D printing enables the creation of complex geometries and intricate designs that are impossible or cost-prohibitive with traditional manufacturing methods.

Innovation: This design flexibility fosters innovation, allowing businesses to experiment with new product ideas and quickly bring them to market.

Applications of 3D Printing in Custom Manufacturing

Healthcare:

Prosthetics and Orthotics: Custom-fit prosthetic limbs and orthotic devices can be tailored to individual patients, improving comfort and functionality.

Medical Models: 3D printed anatomical models assist surgeons in planning complex surgeries and improving patient outcomes.

Aerospace and Automotive:

Custom Parts: Aerospace and automotive industries benefit from 3D printed custom parts for prototyping, tooling, and end-use components.

Lightweight Structures: The ability to create lightweight, complex structures enhances fuel efficiency and performance.

Consumer Goods:

Customized Products: From personalized phone cases to bespoke kitchenware, 3D printing allows small businesses to offer unique products that cater to individual preferences.

Replacement Parts: Consumers can obtain hard-to-find or discontinued parts for household items, extending the life of products.

Fashion and Jewelry:

Bespoke Designs: Designers can create custom jewelry and fashion accessories with intricate details, offering personalized and exclusive items.

Sustainable Fashion: 3D printing reduces waste in the fashion industry by producing items on demand and minimizing excess inventory.

Challenges in 3D Printing for Custom Manufacturing

Material Limitations:

While the range of printable materials is expanding, there are still limitations in terms of strength, durability, and functionality for certain applications.

Production Speed:

3D printing can be slower than traditional manufacturing methods for large production runs, making it less suitable for high-volume production.

Post-Processing:

Many 3D printed objects require post-processing, such as sanding, painting, or curing, which can add time and labor costs.

Skill Requirements:

Operating 3D printers and optimizing designs for additive manufacturing requires specialized knowledge and skills, posing a learning curve for small business owners.

Future Prospects and Innovations

Advancements in Materials:

Ongoing research is expanding the range of printable materials, including metals, ceramics, and biocompatible materials, broadening the scope of applications.

Improved Printing Technologies:

Innovations in printing technology, such as multi-material printing and faster print speeds, will enhance the efficiency and capabilities of 3D printing.

Integration with IoT and AI:

The integration of 3D printing with the Internet of Things (IoT) and artificial intelligence (AI) will enable smarter manufacturing processes, predictive maintenance, and automated quality control.

Sustainable Manufacturing:

As sustainability becomes increasingly important, 3D printing offers eco-friendly manufacturing solutions by reducing waste and enabling the use of recycled materials.

Benefits of Incorporating 3D Printing in Custom Manufacturing

Customization and Personalization

- Tailored Products: 3D printing enables the production of bespoke items that cater to individual customer specifications, enhancing customer satisfaction and loyalty.

- Mass Customization: Businesses can efficiently produce small batches of customized products without significant cost increases, blending bespoke and mass production benefits.

Cost Efficiency

- Material Savings: Additive manufacturing uses only the necessary material to create an object, minimizing waste and reducing material costs.

- Tooling Cost Reduction: 3D printing eliminates the need for expensive molds and tooling, making it cost-effective for prototyping and low-volume production.

Rapid Prototyping and Production

- Speed to Market: 3D printing accelerates the design and prototyping phase, allowing for quick iterations and faster time-to-market.

- In-House Manufacturing: Small businesses can manage production internally, reducing reliance on external suppliers and shortening lead times.

Complexity and Innovation

- Design Freedom: 3D printing allows for the creation of complex geometries and intricate designs that are difficult or impossible with traditional manufacturing methods.

- Encourages Innovation: The flexibility of 3D printing fosters experimentation with new product ideas, enabling businesses to innovate and stay competitive.

Reduced Supply Chain Dependencies

- Localized Production: 3D printing enables localized manufacturing, reducing dependence on global supply chains and associated risks.

- Inventory Reduction: Businesses can produce items on demand, minimizing the need for large inventories and reducing storage costs.

Environmental Sustainability

- Reduced Waste: Additive manufacturing produces less waste compared to traditional subtractive methods, contributing to more sustainable production practices.

- Recyclable Materials: Many 3D printing materials are recyclable, further enhancing the environmental benefits of this technology.

Competitive Advantage

- Differentiation: Offering customized and innovative products can differentiate a business from its competitors, attracting new customers and retaining existing ones.

- Adaptability: The ability to quickly adapt to market changes and customer demands provides a significant competitive edge in dynamic markets.

FAQs

1. What is 3D printing and how does it work?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital file by building them layer by layer using materials like plastic, resin, or metal.

2. How can 3D printing benefit small businesses?

3D printing offers small businesses the ability to produce customized products, reduce production costs, speed up prototyping and production times, and innovate with complex designs.

3. What are the main challenges of using 3D printing in custom manufacturing?

The main challenges include material limitations, slower production speeds for large runs, the need for post-processing, and the requirement for specialized knowledge and skills.

4. What are some common applications of 3D printing in custom manufacturing?

Common applications include healthcare (custom prosthetics), aerospace and automotive (custom parts and lightweight structures), consumer goods (personalized products and replacement parts), and fashion and jewelry (bespoke designs).

Final Words

3D printing is revolutionizing bespoke manufacturing, giving small firms unprecedented prospects for creativity, cost reductions, and competitive advantage. Small firms may meet the need for individualized products, cut production costs, and speed time-to-market by using this technology. 3D printing in bespoke manufacturing is promise as materials and printing technologies develop, ushering in a new era of innovation and efficiency.